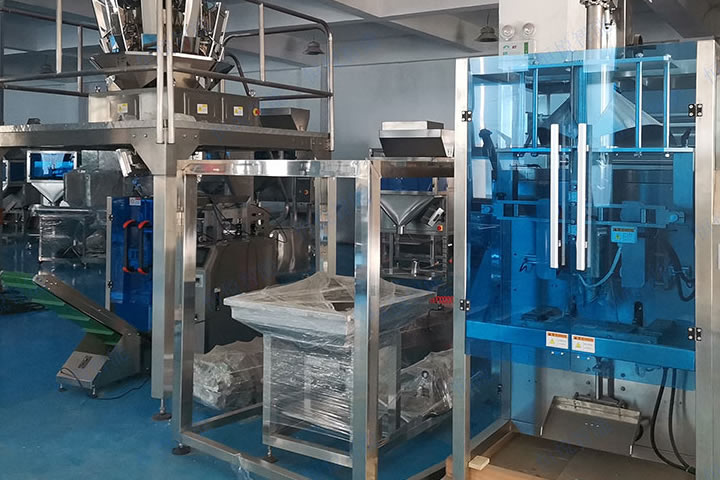

In a clean workshop of a pharmaceutical factory on the outskirts of Bangkok, Thailand, a micron-level dust is enough to put the entire batch of drugs at risk of being scrapped. Ananda, the production line supervisor, stared at the newly put into operation equipment-the silver-gray body and the transparent sealed cabin, the powder raw materials were being packaged in an almost silent rhythm, and the data jumping on the display screen was stable in the green range of ±0.1 grams. "This is ply-pack's high-precision powder packaging machine, which has completely changed our production dilemma." Ananda said with emotion.

The pharmaceutical company mainly produces antibiotic powders, and has extremely high requirements for packaging accuracy and workshop cleanliness. The traditional equipment used previously had large fluctuations in weighing errors (±0.3 grams) and insufficient sealing, which not only resulted in more than 200 kilograms of raw materials being wasted every month, but also caused multiple quality inspection failures due to dust spillage. The hot and humid climate in Southeast Asia exacerbates the risk of metal parts rusting, further amplifying the problem of equipment stability.

After an on-site survey, the ply-pack technical team customized a solution integrating three core technologies:

.Intelligent weighing system: Equipped with a dynamic compensation algorithm, it senses temperature and humidity changes in real time and automatically calibrates parameters to lock the error at ±0.1 grams;

.Fully sealed dustproof process: The feeding port and the bag discharge station adopt a double-layer airtight design, combined with a negative pressure dust removal device, to achieve dust residue ≤0.01 mg/m3;

.Tropical moisture-proof upgrade: Key components are made of nano-coated stainless steel, which increases corrosion resistance by 60% and is suitable for the high humidity environment in Southeast Asia.

After the equipment was put into operation for three months, the production data of the pharmaceutical company improved significantly:

· The loss rate of raw materials decreased by 42%, and the annual cost savings exceeded 1.8 million baht;

· The quality inspection pass rate jumped from 87% to 99.6%, and successfully passed the FDA flight inspection;

· The cleaning time of the workshop was reduced from 2 hours a day to 30 minutes, and the production capacity increased by 25%.

Ananda wrote in the acceptance report: "This high-precision powder packaging machine is not only a piece of equipment, but also our "passport" to open the international market." Today, the pharmaceutical company has listed ply-pack equipment as a standard for new production lines, and plans to jointly develop upgraded models suitable for nano raw materials.

As the regulatory standards of the pharmaceutical industry in Southeast Asia are aligned with international standards, high-precision powder packaging machines are evolving from "production tools" to "quality endorsements". ply-pack uses technology to break the dilemma of the game between precision and cleanliness, allowing more companies to see the hard-core power of "China's smart manufacturing".